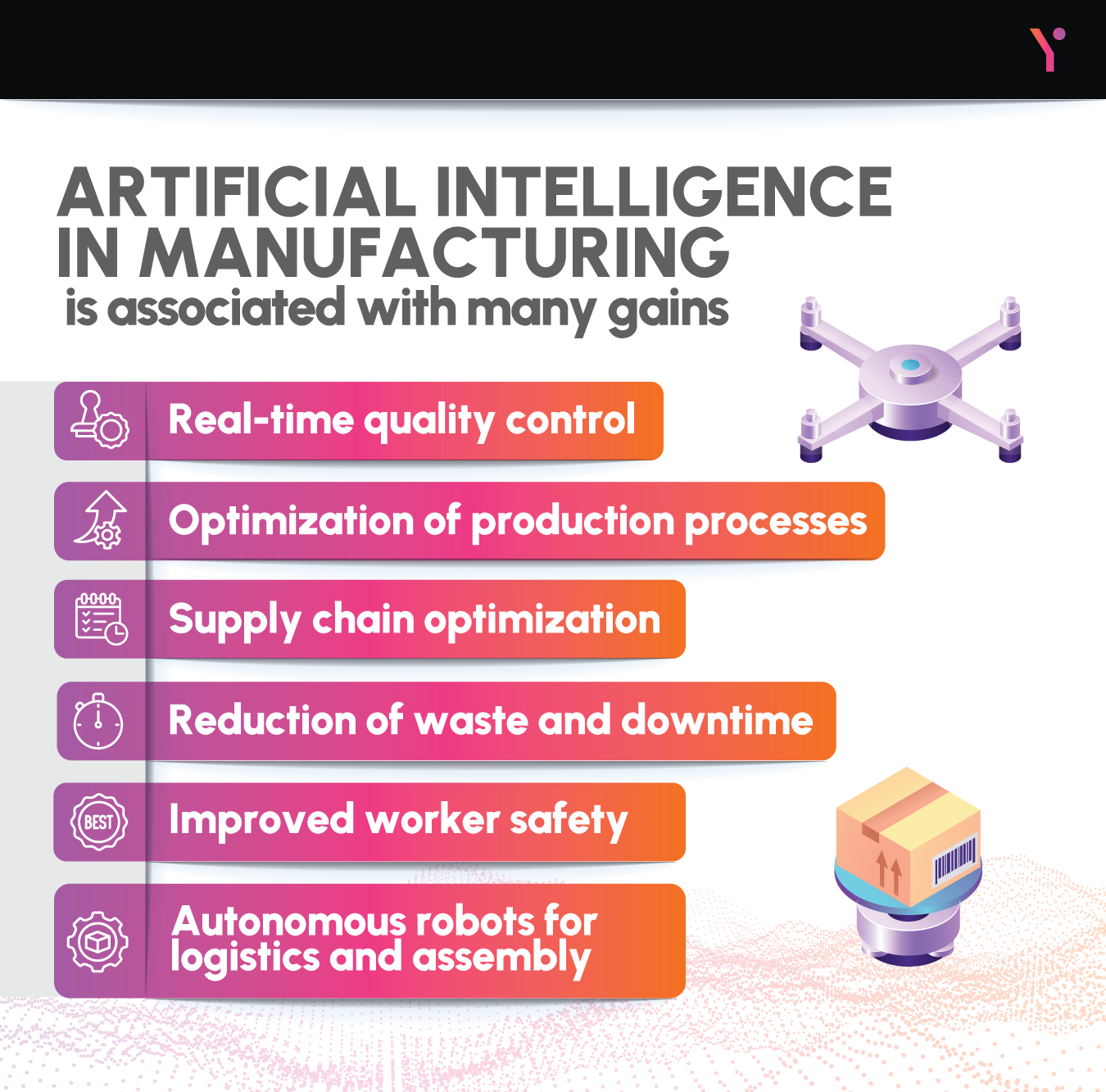

This blog discusses AI in manufacturing. It discovers the following key points –

- The role of AI in manufacturing

- AI in the Manufacturing Industry – Important Use Cases

- Impact of AI in Manufacturing and its benefits

Throughout the past decade or so, Artificial Intelligence (AI) has seen an exponential level of growth. This is associated with its seemingly limitless potential and capabilities. Many experts are of the view that AI should be considered as a science that becomes a teacher for machines by letting them know how to think. This is why AI is able to shape industries throughout the world. Surely, you must have already heard about AI in Manufacturing or AI elsewhere, such as in technology solution services or perhaps in an entertainment application.

Another prominent fact is that today, AI is already playing a big role in our routine lives. You can be at home making good use of Alexa or at a hospital where your illness is being diagnosed. It is its overall ability to get integrated into processes and systems that have opened the door to wide-ranging possibilities. Throughout industries, AI can make way for unimaginable innovation, enhance efficiency, and even boost productivity. Already, many workshop management software systems and real estate reporting software tools are making phenomenal use of it.

Another mind-boggling fact regarding AI is that it can act as a game-changer across industries. This is evident from the fact that AI continues to make a definitive mark throughout industries. Now that you have a good idea of what AI is capable of, let’s dive into the key subject matter of this blog, which is AI in Manufacturing. Let’s see how this technology is a game changer and why it is fair to state that it opens up a host of opportunities for both the near and far future.

The Role of AI in Manufacturing

In terms of manufacturing, AI has various applications. This includes the management of the supply chain to quality assurance.

AI in Manufacturing – The Existing Applications

It is openly understood that AI is a wonderful tool for the manufacturing sector, which is present throughout the world. There are already places where AI in manufacturing is able to play a pivotal role in developing the modern manufacturing process. A prominent example here can be taken of quality control. Since AI can rapidly analyze a great amount of data, this allows it to be much better than humans when it comes to the detection of product-related defects that can easily go unnoticed.

A great example of how AI facilitates quality control is image recognition. When a process permits AI to visually inspect all the products present on the production line, defects will be quickly detected with the aid of meticulous analysis. This is why there will be better quality and cost savings.

There are AI algorithms that permit predictive maintenance to be streamlined. It also lets them become highly efficient for the purpose of mainstream adoption. One of the many unique characteristics of AI is scrutinizing data from machine sensors. This is for the purpose of the identification of potential faults before they become cost-consuming disruptions. This highly proactive approach goes on to enhance efficiency by decreasing downtime, thereby allowing greater overall productivity.

There are AI-supported demand forecasting tools that let any manufacturer better anticipate demand, thereby accordingly adjusting the production. One of the many gains of any such system is that it optimizes resource allocation, decreases waste, and conducts a highly efficient manufacturing process.

AI in Manufacturing – The Benefits

There are a host of benefits that you stand to gain via AI’s impressive integration into manufacturing processes. As hinted above, one of these is cost reduction. Other benefits include better product quality and a greater degree of supply chain efficiency achieved.

Decrease in Costs

Thanks to efficient resource allocation and predictive maintenance, a company will see superior equipment performance. This will then let them save significantly on downtime and repair costs. One report by McKinsey highlighted that those businesses that have made use of AI in their respective operations have reported a 10% decrease in their production costs.

Better Efficiency

A system powered by AI will be able to streamline a manufacturing process. As a result, there will be optimization in production schedules, and this will be based on reducing waste and demand forecasting. For many industries, the reduction of waste is a critical thing, and it is directly associated with their better overall functioning.

Better Product Quality

By applying AI-centric quality control systems throughout a production process, an organization will allow the efficient detection and fixing of defects. These defects could easily go unnoticed otherwise. One study done by McKinsey came to the conclusion that due to AI applications, defect detection rates improved by as much as 90%. This is why more and more manufacturers are demanding AI in manufacturing.

On a side note, many software solutions providers in the retail industry, as well as b, advocate the use of AI.

Let’s glance over some important cases related to AI in manufacturing industry.

AI in Manufacturing Industry – Important Use Cases

The following are some important use cases that highlight the significance of AI in manufacturing industry:

Inventory Management

It is understood that efficient inventory management can be the deciding factor between a million-dollar enterprise and a billion-dollar enterprise. This is where AI has stepped in as a game-changer.

AI in manufacturing has already upgraded a host of processes and operations, and inventory management is considered to be among the most important of them. Thanks to AI-enabled demand forecasting, trends can be predicted highly accurately. Another thing that is predicted is supply chain disruptions, and this is dependent on past data. This is why there will be a substantial reduction in lost sales.

AI will immensely improve demand forecasting, and it will go on to change the way an organization orders its stock. Because AI will be analyzing stock levels, it will now be possible to allow a highly intelligent replenishment. Simply put, AI goes on to monitor your stock levels and compares them to various variables. It will then be in a position that will allow it to quickly detect and order whatever is required. As a result, there will be a significant decrease in stock order errors.

Predictive Maintenance

This is a relatively new concept associated with the manufacturing industry. Note that production facilitates operations by utilizing a maintenance schedule that is organized according to industry standards and manufacturer guidelines. Here, predictive maintenance takes place in this process, and this is done by using the machine learning algorithm’s analytic capabilities in tandem with the Internet of Things (IoT) sensors’ data.

Thanks to this process, small anomalies that highlight machinery failures prior to their occurrence will be accurately detected. This is why downtime will be minimized and operation efficiency thoroughly optimized.

Quality Control

This is commonly regarded as an important part of the entire manufacturing process. This ensures that the quality of products is as required and confirms that the products meet the already established criteria and standards. This will go on to determine whether a company will enjoy immense success or absolute failure. As highlighted above, AI can play a huge role in improving the overall quality control process.

Because of AI-powered automated inspections, every single product item will be scanned for variations and defects. Therefore, it will be possible to improve defect detection rates by as much as 90%. This technique can decrease costs and significantly improve inspection-related accuracy.

Logistics and Auto Transport

Logistics and auto transport are generally considered to be the mainstay of supply chain operations. This ensures efficient raw material delivery to factories and the delivery of finished goods to the market. All of this has an immense effect on customer satisfaction, production efficiency, and the business’ overall profitability.

Here, AI’s role is highly important as it enhances the manufacturing process by optimizing logistics and auto transport operations. When AI performs the analysis of previous patterns associated with this functionality, it can suggest optimal routes, predict traffic patterns, and even predict future events. All of this means that there will be a lower amount of fuel consumed and a decrement in transit times. As a result, an organization will enjoy better profits as it will be able to cut costs and attain supply-related improvements.

Production Planning

It is generally believed that production planning is a vital component of the entire manufacturing process. It is supposed to ensure the highest levels of effectiveness and efficiency throughout the production process. This is why it is considered to be a great place for AI-powered applications.

We are witnessing that AI is able to immensely improve production planning with the aid of methods similar to various production processes. As AI goes through past data on resource allocation, output levels, and production schedules, it can identify trends and patterns. The result is that an organization can better optimize production planning.

Concluding Remarks

It has been understood that AI can revolutionize the entire manufacturing industry. This will be done as it plays a vital role in improving safety, productivity, and efficiency. However, this does not mean that everything is perfect when it comes to AI in manufacturing. There are substantial challenges associated with skill gaps and initial investments. While you are on this topic, please also take a look at the latest in on demand software development as well as fintech software development.

Finally, take note of the fact that Futurbyte is a well-renowned software solutions provider that offers ground-breaking technology solutions to organizations looking to make the most out of artificial intelligence.

Frequently Asked Questions

It is a well-known fact that artificial intelligence is altering manufacturing by enhancing product quality data, predicting maintenance needs, and optimizing production efficiency. All of this is done with the assistance of data-driven insights.

Sure, artificial intelligence is being used for supply chain optimization, demand forecasting, quality control, predictive maintenance, and autonomous robots for logistics and assembly.

It is the job of artificial intelligence to analyze data from cameras and sensors in order to detect real-time defects. All of this will enable early intervention. As a result, a business will be in a better position to ensure high product quality.

It is the role of the artificial intelligence algorithms to properly analyze equipment sensor data in order to predict potential failures. This will then pave the way for the minimization of downtime and proactive maintenance.

The right artificial intelligence algorithms are supposed to analyze a great amount of data, and this is done in order to enhance efficiency, decrease costs, improve forecasting accuracy, streamline logistics, and optimize inventory levels. Already, there are a great number of examples throughout the world where artificial intelligence has been able to optimize supply chain management, thereby resulting in better profits. These examples exist across industries.

Have questions or feedback?

Get in touch with us and we‘l get back to you and help as soon as we can!